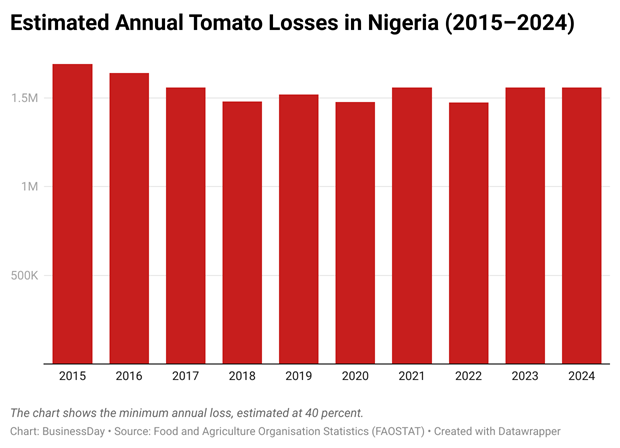

Nigeria produces millions of tonnes of fresh tomatoes annually, yet much of the crop goes to waste for lack of processing capacity.

Meanwhile, the country imports roughly 400,000–520,000 tonnes of processed tomato paste each year, costing hundreds of millions of dollars. That gap between farm output and factory capacity is the investment opportunity.

Market size & trajectory

The domestic tomato-concentrate and paste market is growing. Estimates put the local tomato concentrate market at low single-digit millions of dollars today, with projections of mid-single-digit CAGR into the decade; global processed-tomato markets show a 4 percent – 6 percent CAGR, which suggests Nigeria’s processed-tomato demand can expand similarly as urbanisation and convenience food consumption rise.

Using import volumes (400, 000 – 520, 000 tonnes) and prevailing paste prices, the immediate addressable market for processed tomato products in Nigeria is worth hundreds of millions of dollars annually, with room to substitute imports and build export capacity.

Where to locate raw materials and processing plants

Tomato production is concentrated in the north and middle belt, Kano, Katsina, Jigawa, Kaduna, Niger, Borno, Kebbi and Sokoto making these states priority sourcing hubs. Locating primary processing (sorting, canning/puree lines, dehydration) close to these clusters reduces spoilage and inbound freight.

For value-added packing and access to consumer markets, secondary sites near Lagos or Ogun (for domestic retail and export), and a major inland hub in Kano/Kadawa (already a processing cluster) make operational sense. The Dangote and other private efforts in Kano demonstrate the practical case for locating large processing capacity in the north.

Tomato powder: a first-mover play

Nigeria has few large industrial tomato-powder manufacturers; most powder suppliers are small or traders rather than scaled processors, leaving room for an industrial entrant to own the category. Powdered tomato sells at higher margins, has long shelf life, and fits industrial foodservice, seasoning, and export markets.

A decentralised model small drying/atomisation units sited beside collection depots, plus a central plant for milling, blending and packaging mirrors the sachet-water model: cheap capex, rapid payback, and wide distribution potential. (Note: small local suppliers exist, but no dominant large-scale domestic tomato-powder brand has emerged.)

Market channels and best marketplaces

Domestic retail (supermarkets, open markets), fast-moving consumer goods (FMCG) manufacturers, foodservice, and institutional buyers (schools, hospitals) form the core demand. Export to neighbouring West African markets and West African food processors is a second tier, African processors still import paste in significant volumes, creating export opportunities for competitively priced Nigerian paste and powder.

Urban centres (Lagos, Abuja, Port Harcourt) and regional distribution hubs in Kano and Kaduna are priority marketplaces.

Risks and mitigants

Key risks: seasonality and supply volatility; post-harvest losses; infrastructure (power, cold chain) constraints; quality-control and standards; and FX/fiscal policy swings that affect input imports.

Mitigants include vertical integration (farm aggregation and cold storage), contract farming, investments in solar drying/dehydration, and securing offtake contracts with retailers and food manufacturers. Public–private partnerships and recent private investments into processing capacity (example: large plants in Kano) reduce execution risk.

Why invest now

The economics are simple. Substituting imported paste, capturing export inflows, and creating a high-margin powdered product create multiple revenue streams. Low-capex decentralised processing (the sachet-water logic) shortens working capital cycles; centralised value-add yields margins.

With growing urban demand and limited large-scale powder producers, early movers who secure raw material through aggregation and invest in dehydration and canning capacity stand to capture market share, reduce import dependence and build an exportable brand.