Collective Power Engineering Limited, a fast-rising energy solutions provider based in Port Harcourt, is calling for a government policy that will check the importation of certain levels of energy-generation equipment that could be produced and assembled locally.

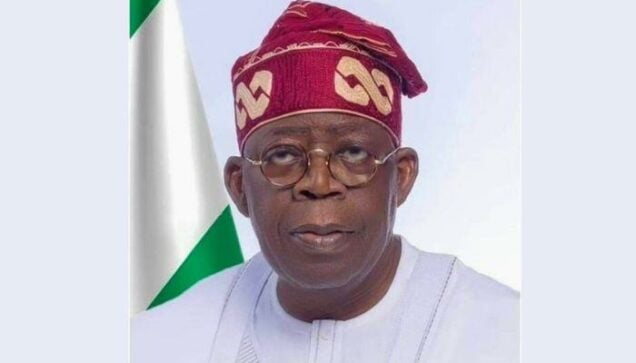

Managing Director of Collective Power Engineering Limited, Oghenetega Ekpamako, said with such a policy in place, indigenous companies like his could apply their knowledge capacity to build more local content in the energy sector and facilitate the country’s industrialization without dependence on third parties.

The entrepreneur made the call during an interview with BusinessDay shortly after the official opening of Collective Power Engineering Ltd’s operational facility in Rukpokwu, Port Harcourt, recently.

He said: “It’s not just going to be revenue generation; there is going to be capacity in terms of knowledge base. And what that will do for us – it means we can maintain our own electrification; we’re not dependent on third party to move our own industrialisation.”

The Collective Power Engineering Ltd MD said such a local content supportive policy would encourage retainership, sustainability and discourage the brain drain syndrome partly responsible for Nigeria and Africa’s developmental backwardness.

“If we have the right policy in place to grow the volume of sales, we will be able to have enough revenue to be able to retain and sustain that capacity. Government should put a policy in place. At least we should be able to identify certain electrical products which should not be imported as full assembled products. For me, anything from a low voltage level – from 60 to 90 downwards – we can source and get that quality in the country,” he said.

Ekpamako said Collective Power Engineering Ltd, since commencing operation three years ago, had been investing in the capacity building of its team of engineers through engagement with global experts, knowledge sharing and regular training and retraining programmes.

“When we came into the Nigerian space, the first step we took was to invest in capacity building. I’m engaging global manufacturers, they come in, we have monthly, bi-weekly knowledge sharing to ensure that we understand and we can in return replicate. We’ll be going abroad to see how those technologies are being designed, implemented and maintained,” he said.

Highlights of the event were the ribbon-cutting ceremony to officially open the company’s operational facility and presentation of award to some of their staff.

Members of the Port Harcourt Chamber of Commerce, Industry, Mines and Agriculture (PHCCIMA), led by their president, Chinyere Nwoga, graced the occasion.