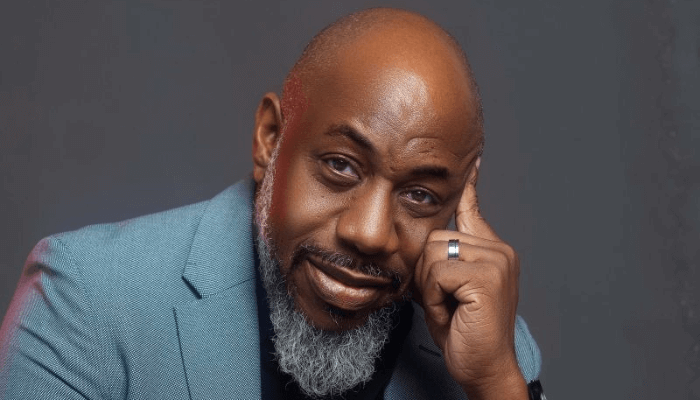

Raj Gupta is the chairman of African Industries Group, a consortium of 12 companies, including six steel plants. Gupta tells ODINAKA ANUDU, in this interview, that steel makers in Africa’s biggest economy are going through tough times. He describes the federal government’s import restriction policy as a bold step that could transform Nigeria into an industrial hub in the long run.

Tell us what you do in African Industries Group.

African Industries Group has 12 manufacturing plants across Nigeria.  Out of these, six are steel manufacturing plants. All together we produce one million metric tonnes of steel, accounting for 60 to 70 percent of the steel requirements of Nigeria. Our plants are situated in several states across the federation. We have African Steel Mills and Ikorodu Steel Mills in Lagos State. In Ogun State we have African Foundries, Ogijo, as well as African Wire & Allied Products, Agbara. We also have Abuja Steel Mills and another steel mill in Port Harcourt.   Apart from this, we make glass and alum. The alum is used in the water treatment chemical. We are generate power. At the moment we are connecting about 118 mega watts of power to the national grid. We also refine and export lead and earn foreign exchange; this plant is only focussed on exports.

It is obvious you are doing a lot for the economy. But are you, like many other manufacturers in the country, affected negatively by foreign exchange restrictions and capital control?

We commend the efforts made by the government and the Central Bank of Nigeria (CBN) to support the real sector in Nigeria, to generate employment and help the country not to be dependent on imports. The oil price is low, the foreign exchange is scarce, and Nigeria is poised to grow its industrial base.

I feel that the steps taken by the government are commendable, because this is about the survival of Nigeria. Most developed countries like the European Union (EU), the United States of America and others have put anti-dumping laws on Chinese steel because of unfair advantage of prices through subsidy in China. So the step taken by the government is right.

But do you import raw materials?

Yes, we import a lot of raw materials, consumables and spare parts for our factories. This is very important for us. When the government banned foreign exchange on certain products, it freed up forex for inputs needed for our factories. The government has discouraged import of finished products, which are not essential to Nigeria, or not manufactured in the country. So it really supports industries and manufacturing sector.

So import restriction has raised the demand for your products?

There is a general lull in the economy.  But I would say that if these measures had not been implemented, our situation would have been worse. I would not say we are doing well, but it prevented a situation where we would be doing worse.

How then do you source forex for your numerous imported inputs?

We source them through our banks, which gets from the central bank.

But do you get enough forex from your bank?

Not enough. It was very bad towards the end of last year. But I think the government has taken steps to resolve that.

So you get forex at the official rate?

Yes.

With import restriction in place, do you and other players in the steel industry have the capacity to meet local demands?

Steel capacity in Nigeria is two and a half times the demand. We, along with other manufacturers, installed capacity in anticipation of continuous growth in the economy.

What about capacity utilisation?

Utilisation is low because the demand is low at the moment. It has been low for a year and it is likely to change once the infrastructure spend comes through the budget. Most of the construction companies have not been paid for the jobs they have done. Once the construction companies are paid, they pay our dues which are outstanding and place new orders. When this is done, the demand automatically rises.

How is the steel sector performing so far?

The steel sector is the backbone of any major economy in this world.  Without steel, there cannot be any other industry in the real sector of any economy. The government has spent billions of dollars trying to develop the economy, but it has not worked. We are the major players in this sector and with the new budget already passed, we are hopeful the demand will go up.

The government is planning to resuscitate Ajaokuta Steel Complex. How will this help the steel industry?

Currently, I am not sure those technologies are competitive in steel making. The world has moved on. What is required now is for the private sector to get more and more involved in the downstream and the upstream segments in the steel business. Currently, our group is exploring mining options. This is what is needed right now.

But the government has always talked about Ajaokuta Steel as one plant that can save the steel industry and indeed the manufacturing sector…

Internationally, steel is going through a very rough time. Just like oil, most of the commodities are in all-time low, and steel is in a similar situation. Plants like Ajaokuta are only viable when steel prices are substantially high, because many of the technologies there are old. So currently, operating a plant like Ajaokuta will be at a loss.

But some of you in the industry are still doing well?

No, we are not doing well, owing to the demand issue. If the demand picks up, we will be able to go back to our activities.

About how much has your group invested so far in the steel industry?

We have invested over a billion dollars in total.

So how will the government help to reverse the fortunes of the steel industry?

Like I said earlier, the steel sector is the backbone of any economy. Government needs to, first of all, recognise that the sector is really benefitting the country.  There is the need to put a local content policy in place whereby all the steel users and all the government contractors should stipulate they must buy made-in-Nigeria steel. They should, like most other countries in the world, look at how to prevent cheap and substandard products coming in from China. The United States, the European Union and many countries have put anti-dumping duties on Chinese goods.  The Nigerian government should look at doing this. The major thing, again, is the cost of doing business in the country. It is very, very high. The interest rates are high. I believe that there should be a fund to support the steel sector because no industry can flourish over a long time if the interest rates are double-digit. Government support is required in this area.

But you have the Bank of Industry (BoI), which has supported companies like yours?

They are still at ten percent. We need to look at something lower.

What else do you export, apart from lead?

We export commodities such as sesame seeds, cashew and agro commodities. Currently, we are looking at putting up plants in Nigeria that will give us value-addition by treating them and ensuring they go through some processes.

Let us talk about jobs. How many have you created so far?

Our business is very peculiar. Apart from 8000 people we employ in our group, I believe indirect employment in our sector is unusually very, very high. This is because we are buying a lot of raw materials like scrap. This scrap is collected by unemployed people. Most of them are unskilled. In the value chain, you have people who collect scrap; people who buy; and people that are involved in transporting scrap. There are distributors, transporters and agents involved. The value chain is just huge. Unlike other industries where a lot of raw materials are imported and the value chain is short and not in Nigeria, our value chain is long and comprises mainly Nigerians.

You are bringing in foreign exchange. Has there been any support from government?

In the past there used to be the Export Expansion Grant (EEG) that was recognising that the cost of doing business in Nigeria was high. Perhaps, government should look at that.

The suspension of EEG and the crash on steel prices are preventing our steel from being exported. We were exporting a lot of manufactured products (in Nigeria) to the whole of ECOWAS region before the EEG was suspended.

How competitive are your products in the global market?

They are not very competitive simply because international prices have crashed; cost of doing business in Nigeria is high, and the EEG is gone.  So it becomes very difficult for us to be competitive in the international market.

Have you ever taken any waiver from the government to import inputs like billets?

No

Why?

Billet is duty-free. You do not need a waiver to import it.

You have been talking about low international prices. But we still have relatively high domestic steel prices?

Prices are high because costs of running a business in Nigeria are tremendous as mentioned earlier. Besides, mills run at very low capacity due to poor demand, increasing the costs of production. Steel prices in Nigeria are still very, very low as compared to the global prices.

But I know we have a lot of infrastructure challenges, particularly housing shortages, in the country?

If you go to the market now, you will see that virtually everything there is made-in- Nigeria. The policy of government has helped the local industry to re-establish itself. I would also like to add that steel has many grades. International companies that make high-rise buildings, bridges and other construction work requiring quality steel now patronise us. In the past they were not comfortable buying from us, but this has changed. Our company has an international certification for quality of steel. Now, you don’t compare our steel with Chinese or Ukrainian steel.  You compare what we produce with Japanese and German steel. And now, virtually all the construction companies are buying made-in-Nigeria products. This could be further enhanced by government putting in legislation to that effect.

There was a time some steel firms, particularly the roofing sheets segment, reduced the quality of their products so as to be able to compete with Chinese  products. Did this affect your sector?

It did not affect our sector. In fact, our sector is a critical one. If any compromise is made with the quality of steel, we will be talking about collapse of buildings. If it were in roofing sheets, it will be only a matter of how long the product lasts. The leakage of the roof may not be life-threatening.

During a debate on building collapse in 2014, some experts apportion blame on iron rods used in construction. How true is this to you?

No, the easiest cause of this kind of problem is lack of engineering, where the quantity of steel and cement used is far lower than design standards.

Secondly, it is about the contractors doing their job. If they are not doing it professionally, that is where the problem comes in. Quality iron rods and cement are available in Nigeria.

How do you cope with production cost?

It is very, very difficult. We are going through difficult times. We need all the support we can get today. Regarding power, we have done backward integration. We generate our own power; that is one of the reasons why we are still able to survive. The major issue is the demand side. Demand is very low and the capacity is at least double of what we are producing.

You are mining in some parts of the country. What is your experience like?

There is a need to do beneficiation on some of the iron ores found in the country. A lot of iron ores here still need beneficiation. So the issue of beneficiation, phosphorus and other impurities have to be resolved. The cost of doing these is high, and this is where the government comes in.

But exploration is not rocket science. But the main issue is that steel prices internationally have been so low, and even lower in Nigeria.  The cost of mining is so high. Transportation cost may be a serious obstacle also and the government needs to invest in infrastructure. That is why I said that without support from the government, these efforts may not take off.

So what should the present government do to raise the manufacturing sector from the ashes?

I urge the ministers that were appointed late last year to start physically visiting the real sector companies, look at their problems and their activities so as to see how they can help solve key problems.

How confident are you in the Nigerian economy?

I am confident in the long term because of the demographics and need for investment. I am also glad to see a government working through issues. We need the government to engage the real sector of the economy to address their infrastructure and financial cost issues.

ODINAKA ANUDU