Not long ago, inflation was considered the villain in every boardroom story: a relentless force that squeezed margins, limited spending, and tested the resilience of even Nigeria’s biggest consumer brands. Every shipment, salary, and sales plan had to adapt to its impact. Diesel prices doubled, the naira faltered, and imported inputs became luxury items overnight. In the midst of this chaos, something remarkable happened: Nigeria’s FMCG firms refused to give up.

What once felt like an economic chokehold is now becoming a trigger for reinvention. Across factories and strategy sessions, FMCG leaders are no longer just firefighting; they’re redesigning the system. Procurement teams are rethinking raw-material sourcing; operations heads are digitising logistics; marketers are reinventing packaging to match thinner wallets and faster-moving consumer trends.

The result? A quiet transformation: born not of comfort, but of constraint. Inflation’s heat didn’t just burn; it forged a tougher, smarter, more adaptive FMCG industry. And yet the looming question remains: Can this newfound agility outlast the crisis that inspired it, or will the renaissance fade when the pressure lifts?

The Inflation jolt and FMCG reality

For most players, costs increased significantly in 2024 due to higher commodity prices and currency depreciation. An additional factor was the rise in operating, transportation, and logistics expenses. However, by the second half of 2025, Nigeria’s inflation finally slowed, dropping to 18.02% in Q3, marking its sixth consecutive month of decline and its lowest level in three years.

The moderation offered a glimmer of relief, but beneath that surface calm, familiar headwinds persist. The Lagos Chamber of Commerce and Industry (LCCI) warns that, without decisive reforms, structural bottlenecks, energy costs, FX instability, and supply chain inefficiencies that remain evident could derail the gains.

For Nigeria’s FMCG sector, this isn’t just another macroeconomic headline; it’s a real-time stress test. Rising production, packaging, and haulage costs continue to compress margins, while weakened purchasing power forces brands to reinvent how they deliver value. In this pressure cooker, innovation is taking root.

The sector’s leading players are not standing still. CardinalStone Research notes that easing inflation and a firmer naira are setting the stage for margin recovery in Q3 2025, driven by more innovative cost controls and renewed consumer demand.

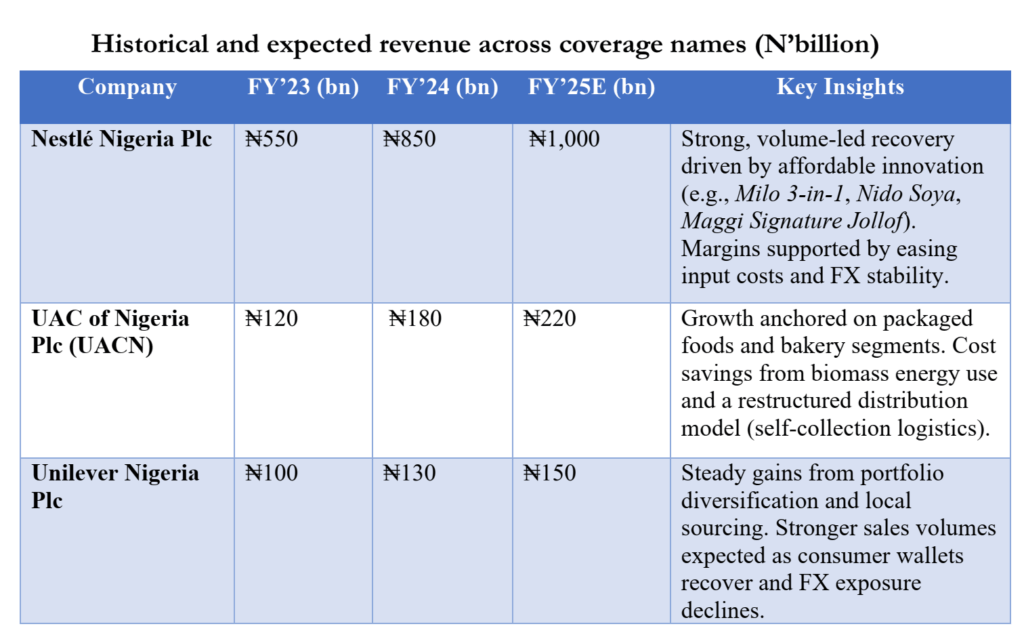

- Nestlé Nigeria is expected to post stronger results, buoyed by volume recovery and input cost moderation.

- Unilever frontloaded raw material purchases to hedge against inflation, leveraging a deleveraged balance sheet to cut finance costs.

- UACN introduced biomass boilers to offset high diesel expenses and overhauled distribution networks to trim surcharges.

- BUA Foods, meanwhile, focused on expanding profitable bakery segments as global sugar prices eased.

Across the board, firms are localising sourcing, digitising distribution, and refining portfolios to protect margins. The inflation jolt, though bruising, is becoming a catalyst for renewal; forcing Nigeria’s FMCG giants to abandon old inefficiencies and rewire their value chains for agility, efficiency, and long-term competitiveness.

Inside the squeeze

Due to cooling price pressures, the relief was more statistical than structural. For many sector players, the cost storm never truly passed.

Input, energy, and logistics costs continued to rise, squeezing margins even as the naira stabilised. Inside boardrooms, FMCG executives described a “constant balancing act.” Manufacturers faced higher-priced imported materials, while distributors faced record-high haulage costs and security-related surcharges. CardinalStone Research’s Q3 2025 preview confirmed the pressure: although inflation and exchange rates eased, companies like Nestlé, Unilever, and UACN still battled high-cost burdens, delaying capital investments even as slight price increases boosted revenues.

To protect volumes, brands leaned hard into affordability. “Packetisation”, smaller, low-cost packaging — evolved from a stopgap to a mainstream strategy, keeping products within reach of Nigeria’s inflation-weary consumers. Breweries and household goods makers shifted toward mid-tier and value brands, reflecting a decisive consumer trade-down.

Yet beneath the pressure, adaptation took root. Firms streamlined operations, adopted energy-efficient manufacturing, and hedged FX exposure through early material procurement. Unilever cut finance costs by deleveraging, UACN retooled its distribution network to reduce surcharges, and BUA Foods pivoted to its more profitable bakery segment.

Beating the Pushbacks

For Nigeria’s FMCG sector, crisis has evolved into catalyst. The inflation shock of 2023–2024 didn’t just squeeze margins; it has rewired their playbook. Companies were forced to rethink how they source, produce, and deliver, trading short-term fixes for long-term transformation. From localising raw materials to digitising distribution and deploying data-driven pricing, firms are shifting from defensive cost-cutting to structural reinvention.

Margins are no longer supported by subsidies or FX windows, but by efficiency, agility, and local resilience. Disposable income per capita is rebounding sharply, increasing nearly 25% year-on-year in 2025, according to sector estimates, signaling a long-awaited revival in consumer purchasing power. Across the industry, volume recovery is now the main focus. Improved household purchasing power and a modest revival in consumer confidence are driving renewed demand for essential goods. Household spending is projected to reach $373 billion by 2027, with over half allocated to food and beverages, signaling a return of consumer momentum in the sector.¬ÝBut opportunity brings its own challenge: Can innovation survive the crisis that inspired it? Across boardrooms and factory floors, the narrative is changing. Stabilising input costs and recovering demand are powering volume rebounds in essential goods. From packaging redesigns to logistics optimisation and smarter procurement, FMCG leaders are not waiting for stability; they‚Äôre building it.

Innovation as Defense

If inflation was the test, innovation has become the answer. As the FMCG sector steadies from years of volatility, the industry’s most resilient players are no longer waiting for macro relief; they are building agility into every link of the value chain. From Lagos boardrooms to the production corridors of Agbara, a quiet revolution is unfolding: one where speed, innovation, and localisation are redefining competitiveness.

Nestlé Nigeria has become a symbol of this reinvention. Between late 2024 and 2025, it introduced a range of new, affordability-focused products: Maggi Signature Jollof, Milo 3-in-1, Nido Milk and Soya, and Cerelac Rice. These innovations did more than just increase options; they restored volume growth, turning the company’s factories into hubs of consumer insight. By reengineering product formats to be more affordable, Nestlé is not just pursuing market share; it is reaffirming its relevance in an inflation-weary economy.

At UAC of Nigeria, innovation has become more operational. The company’s food division, led by its packaged goods unit, has made significant progress with new launches like Kingsway Pastry Roll and Gala Chin Chin. In addition to product innovation, UAC is restraucturing its cost model: switching to biomass for its boilers and redesigning distribution so that customers can self-collect orders, reducing logistics costs and boosting regional efficiency.

Unilever Nigeria, meanwhile, has doubled down on distribution and local integration. By scaling its regional depots and expanding partnerships with local suppliers, it has reduced FX exposure and ensured steadier product availability. Its broad portfolio, spanning both essential and mid-tier consumer categories, gives it an edge in reaching Nigeria’s diverse consumer base.

Together, these moves represent a broader playbook for resilience. Inflation, once a drag, has become a discipline: forcing FMCG firms to think smarter, move faster, and produce closer to home. The result is a leaner, more adaptive, and future-ready industry, one that’s learning not just to survive Nigeria’s volatility, but to thrive because of it.

¬Ý