Nigeria’s poultry industry is a key-part of the country’s quest for food security and ensuring that it plays a critical role in its diversification quest is crucial to its development.

To address the issue of low technological use in the Nigerian poultry industry, FACCO West Africa is revolutionising the sector through innovative solutions and cutting-edge technologies.

As the leading provider of poultry equipment and automation, they’re helping farmers boost productivity and efficiency. The organisation’s expertise spans poultry, livestock, and agricultural production, offering turnkey solutions, design, and consultancy.

Read also: Uba Sani in China to seal $200m poultry project set to create 350,000 jobs in Kaduna

The organisation’s experience demonstrates that modern agriculture is a business built on technology, engineering excellence, and sustainability—and that African farmers can compete globally when equipped with the right systems.

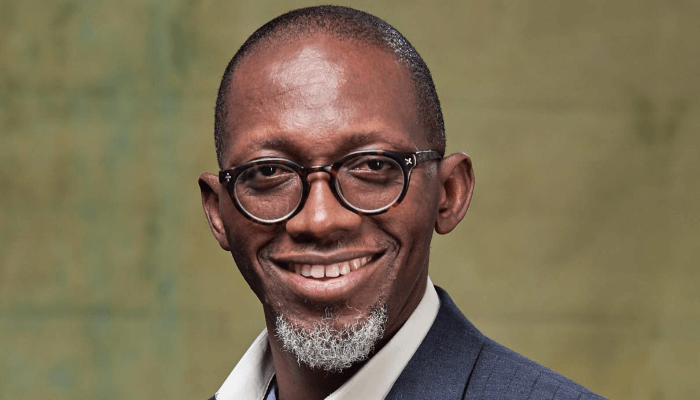

Femi Adelayo, chief executive officer of FACCO West Africa, said that one of the organisation’s flagship deliverables is its advanced poultry housing and cage farming systems, globally recognised for solid construction and hygienic performance.

FACCO West Africa poultry houses are hot-galvanized, waterproof, anti-acid, and corrosion-resistant, offering a guaranteed lifespan even under extreme climatic conditions common across West Africa, Adelayo.

He noted that it is with the highest insulation standards that these systems ensure stable internal environments that protect birds from heat stress while maintaining optimal productivity.

According to him, the organisation’s cage farming systems are the product of a multidisciplinary engineering team comprising experienced engineers, designers, planners, consultants, and in-house zoo-veterinary specialists with global poultry expertise.

“These systems support broilers, layers, breeders, and egg production, delivering high-quality output while meeting the strictest health, hygiene, and animal welfare standards—regardless of climate or geography,” he explained.

“Complementing the housing systems are feeding, drinking, lighting, ventilation, and manure management accessories engineered for durability, hygiene, and ease of cleaning. This reduces labor costs, shortens cleaning cycles, and improves biosecurity—critical factors in modern commercial poultry farming,” he added.

The organisation also delivers state-of-the-art incubators, designed for versatility and universality. With the appropriate egg trays, the same systems can incubate different egg types using shared setter trolleys. Integrated control systems and optimised internal structures maximize hatchability, reduce losses, and significantly increase productivity.

Beyond live bird production, it supports the entire poultry value chain with solutions for live bird handling, slaughtering, evisceration, chilling, cut-up, deboning, and full plant automation, positioning poultry farming as a complete agribusiness rather than a standalone activity.

Read also: How Agro Preciso Ltd is Transforming Poultry Farming in Nigeria with Advanced Hatchery Equipment

FACCO West Africa’s mechanised farming approach extends decisively into post-harvest management—an area where farmers often lose significant value. With a strong passion for post-harvesting, FACCO delivers grain drying systems essential for cereal preservation, ensuring quality retention and profit security after harvest.

Feed storage is addressed through fiberglass and corrugated silos engineered for longevity and performance. Fiberglass silos, available in capacities from 5.5 to 31.5 tons, are lightweight, fully sealed, water-resistant, corrosion-free, and maintenance-free.

Corrugated silos, manufactured from sturdy galvanized horizontal sheets with reinforced bottom rings, are equally sealed against water infiltration and can be insulated and covered for hot climates.

The organisation’s feed mills and pellet press models reflect the company’s commitment to innovation, eco-sustainability, and efficiency. Designed using advanced engineering and modern production technologies, these systems improve pelletising efficiency while delivering value for animals, farmers, and the environment.

In crop production, Adelayo said, FACCO West Africa provides professional greenhouse systems and protected-crop technologies, offering full support from design through installation and after-sales service.

“These solutions are tailored to the needs of both small and large farms, research institutions, and agricultural development programs, ensuring optimal growing conditions for different crops.”

He added that it also delivers complete irrigation and fleet management solutions, combining advanced technology with durable machinery.

“This integration optimises water use, improves operational efficiency, and makes FACCO a preferred supplier of irrigators based on quality, water capacity, technology, and service reliability.”

FACCO West Africa’s livestock solutions go far beyond poultry. In partnership with ACO FUNKI, one of Europe’s leading livestock equipment suppliers, FACCO West Africa delivers full-line solutions for pig production.

These include penning systems, intelligent feeding technologies, flooring, water systems, manure handling, components, and spare parts for both new and existing farms.

The focus is clear: reducing feed waste, minimizing environmental impact, and ensuring optimal animal welfare—key drivers of higher productivity and profitability. The business delivers turnkey pig housing solutions, with high-quality, injury-free pen designs that ensure safety for both animals and handlers.

Precision feeding systems for sows and piglets are engineered to improve feed intake, milk production, and piglet growth, while intelligent liquid manure pipe systems and stainless-steel storage containers enhance hygiene, climate control, and animal health.

In cattle and dairy farming, the organisation provides integrated ranching and farm management solutions that link feeding, milking, waste management, and animal monitoring into a single operational ecosystem.

Optimal farm layouts, automated and semi-automated milking systems, efficient feeding technologies, and livestock waste utilization systems work together to improve cow health, extend lactation cycles, increase milk yield, and reduce operational costs.

Animal-friendly barn designs, automatic feeding systems, and frequent feed pushing stimulate higher feed intake, improving fertility, health, and production outcomes. FACCO’s waste management systems further ensure that livestock by-products are converted into valuable resources, supporting energy generation and crop productivity.

At its core, FACCO West Africa’s mechanised farming philosophy is about helping farmers make the right choices—choices that align with efficiency, sustainability, and long-term profitability. The company’s investments across engineering, people, suppliers, and innovation ensure value creation at every stage of the agricultural value chain.

From poultry to pigs, cattle, crops, feed, storage, processing, and automation, the organisation delivers intelligent, customised, and sustainable solutions that address today’s market realities while preparing farmers for the demands of tomorrow’s society.

As West Africa pursues food security, job creation, and agro-industrial growth, FACCO West Africa stands as a powerful example of how mechanised farming, when done right, becomes a profitable business and a catalyst for sustainable development.