Nigeria’s power sector is navigating a pivotal moment as chronic supply shortfalls collide with renewed reform momentum and rising private-sector investment. Yet a parallel shift is emerging: decentralised and embedded power solutions are gaining traction, offering a more reliable alternative for industries and urban demand centres.

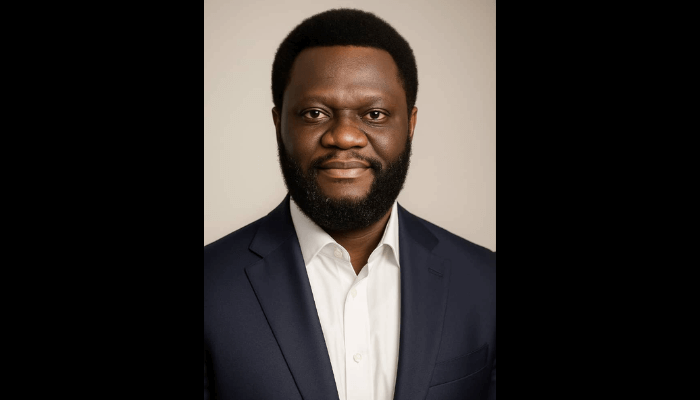

In this interview, Oladipo Ogunniyi, Elektron’s Head of Engineering, discusses the structural gaps still constraining the national grid, the rise of embedded generation, and how projects like the Victoria Island Power Plant signal a new, commercially driven model for dependable, lower-carbon power in Nigeria.

How would you assess the current state of Nigeria’s power sector, particularly in terms of reliability, capacity, and system efficiency?

Nigeria’s power sector is at an important turning point, technically constrained but evolving. We have an installed capacity of about 13 Gigawatts, but only 5–7 GW are consistently delivered to consumers due to constraints across generation, transmission, and distribution. Much of the grid infrastructure is old, overstretched, and unable to support today’s demand.

The encouraging development is the growth of decentralised and embedded power solutions, state-led reforms, and increased private-sector participation. What the sector needs now is optimisation, strengthened transmission, modernised distribution, and integrated, dependable off-grid generation. With a more coordinated approach, we can move from chronic shortages to a resilient, future-ready power network.

You’ve highlighted the structural challenges across the value chain. Where do the most critical bottlenecks lie today – generation, transmission, or distribution?

The biggest constraints are in transmission and distribution. While Nigeria has roughly 13 GW of installed generation capacity, the transmission network can reliably evacuate only about half of that, and even less reaches end users due to technical and commercial losses.

The frequent grid collapses in recent years highlight how fragile the system still is. Between 2022 and 2024, over 15 national grid collapses underscored how fragile the system remains. The solution isn’t to abandon the grid but to reinforce it while complementing it with decentralised generation that eases pressure and improves stability.

Countries like India and Kenya have stabilised their grids with a blended approach combining central grids with regional embedded plants to stabilise supply and accelerate electrification. For Nigeria, generating power close to where it’s consumed minimises losses and delivers a predictable, high-quality supply for industries and communities that can’t afford downtime. It’s a more efficient architecture for a country where demand centers are often far from generation hubs.

How is Elektron Energy advancing reliable, resilient power infrastructure in Nigeria?

Elektron Energy has evolved over the past 14 years from a single-asset operator into a multi-site energy platform powering critical institutions and industries.

Our embedded systems are engineered for continuous performance, reducing reliance on diesel and enabling efficient energy use. The Alausa Independent Power Project, a 10.6 MW gas-fired plant with a 15-km distribution network, has powered Lagos State facilities since 2013, cutting diesel use and proving the viability of embedded generation in urban hubs.

We also power Rack Centre, a Tier III data centre in Ikeja, with 7 MW of scalable capacity, supporting Nigeria’s digital backbone with round-the-clock supply.

Our flagship Victoria Island Power Plant (VIPL), a 30 MW gas-fired facility expandable to 40 MW, will serve Lagos’s main commercial corridor. By providing consistent, cleaner power, VIPL will help businesses transition from diesel to a more stable energy source.

What differentiates Elektron is focus: we build reliable power where it’s needed most, within distribution networks, close to demand centres, reducing losses, improving quality, and ensuring uninterrupted supply for critical users.

Read also: ‘ARM-Harith’s Fund with Elektron facilitates delivery of 11MW Ibadan power plant’

Why focus on Victoria Island, when it’s already among Lagos’s most electrified districts?

Victoria Island (VI) indeed falls largely under Band A, which in theory guarantees at least 20 hours of daily supply from the national grid. In practice, outages remain common and voltage instability persists.

VI is one of Nigeria’s most concentrated commercial hubs, home to financial institutions, hospitals, data centres, and SMEs whose operations can’t afford downtime. The economic cost of unreliable power is enormous; the World Bank estimates that Nigerian businesses lose up to $30 billion annually.

The Victoria Island Power Project creates a dedicated, embedded power ring-fence delivering predictable, high-quality power directly to key clusters. It complements the grid rather than replaces it.

VI was chosen because its demand concentration and infrastructure density make it the ideal environment to demonstrate reliable, private-sector power at scale. Over time, this model can be replicated in other regions, such as the Ibadan Hybrid Power Plant, designed to supply a mixed-use district in Oyo State.

Reliable gas supply is critical to both cost stability and uptime. What’s standing in the way of that reliability, and what models work best?

Nigeria has over 200 trillion cubic feet of proven gas reserves, yet many plants underperform because midstream infrastructure, i.e., pipelines, processing, and distribution, has not grown at the same pace.

That’s why gas logistics sit at the heart of Elektron’s model. In project design, we prioritise a secure, contracted fuel supply and partnerships with established distributors like Gaslink, which have proven networks in Lagos and beyond. Locating plants near both demand centres and gas corridors limits exposure to pipeline disruptions.

Our Alausa IPP, for instance, has operated uninterrupted for more than a decade largely due to a stable gas chain. Countries like Egypt and India show that co-locating generation with gas infrastructure improves reliability and reduces curtailment.

As private operators continue to invest in midstream assets, Nigeria can finally convert its gas abundance into power security, a consistent, cleaner, and more affordable supply.

Some industry observers say that embedded generation projects often face delays due to regulatory or financing hurdles. How is Elektron managing these realities?

They’re not wrong, power projects are capital-intensive, and regulation can be complex, so we take a proactive approach. We engage regulators early, maintain strong partnerships, and phase projects to align funding with progress.

For instance, at Victoria Island Power Limited (VIPL), we began with the infrastructure backbone, completing approximately 12.6 kilometres of dedicated 33-kV and 11-kV distribution network, along with all associated protection, automation, and control systems, before moving into full plant installation.

That early work included network studies, substation integration, and the installation of power cabling in a dense urban environment.

That engineered, phased approach lets us manage risk, demonstrate progress, and unlock financing, including our ₦4.64 billion Series 1 bond under a ₦200 billion programme, supported through Project Halo in partnership with InfraCredit and other institutional investors.

Ultimately, building the distribution network first ensures that, once the gas engines are commissioned, power flows into the system immediately and reliably. It’s a practical, technically disciplined way to accelerate delivery while maintaining quality, safety, and transparency with our partners.

Elektron’s projects have focused on gas-to-power and embedded systems so far. How do these fit into Nigeria’s long-term transition to cleaner energy?

Gas-to-power and embedded systems are bridges technologies, not detours, to cleaner energy. Nigeria’s transition can’t happen overnight, but we can build reliability and efficiency while gradually shifting the energy mix.

Our gas assets already cut emissions intensity by up to 40% compared to diesel while providing stability for growth. Because these plants are modular and embedded within existing distribution networks, they’re designed to integrate hybrid systems, such as solar rooftops, battery storage, or waste-to-energy units, as those technologies mature.

This was the foundation for creating Elektron Renewables Limited (ERL), our dedicated subsidiary driving solar, waste-to-energy, hydro, and storage projects. By 2026, renewables will contribute at least 15% of Elektron’s energy mix, led by the Ibadan Hybrid Power Project and other solar initiatives.

Together, both arms of our business build the bridge from dependable gas power to a diversified, lower-carbon future.

Looking ahead, how is Elektron positioning itself for the global energy transition?

Our focus is on scale and integration. We recognise that the future of power is hybrid, gas providing reliable baseload, renewables scaling quickly as infrastructure matures, and storage bridging the intermittency gap.

While gas remains central to Nigeria’s energy mix for now, we’re already practically exploring renewable integration. That’s where Elektron Renewables Limited (ERL) comes in. Through ERL, we’re developing commercially viable renewable projects: agro-solar systems that power crop processing, hybrid mini-grids for industrial parks, and waste-to-energy solutions. Each is designed for replicability, leveraging our engineering and project-finance experience.

The goal isn’t to switch sources overnight but to build more innovative, adaptable systems that reduce diesel reliance, improve efficiency, and evolve with demand.

For us, it’s not just about changing fuels; it’s about building power systems that work for everyone, reliable, diversified, and sustainable.