In the creeks of the Niger Delta, where much of Nigeria’s oil wealth originates, the country’s energy sector is confronting a critical challenge: how to preserve and extend the life of its ageing infrastructure.

From pipelines and refineries to floating production storage and offloading vessels (FPSOs) and offshore platforms, many of the assets that sustain Nigeria’s oil economy are decades old. Their decline is being accelerated by corrosion, poor maintenance, vandalism, and underinvestment.

The stakes are immense.

According to the Nigerian Oil Spill Monitor, more than 1,500 oil spill incidents were recorded between 2018 and 2023, most linked to deteriorating assets or sabotage.

Each failure carries a heavy cost, lost revenue, environmental damage, community unrest, and a further erosion of Nigeria’s reputation as a reliable supplier of crude. For local oil companies that often operate under tighter margins than international majors, safeguarding infrastructure to extend asset lifecycles has become both an economic necessity and a matter of survival.

The high cost of neglect

Infrastructure failures are not new to Nigeria’s oil sector. For decades, underfunding of maintenance budgets, coupled with economic volatility and foreign exchange restrictions, has created an environment where short-term production gains often overshadow long-term asset sustainability. Yet the costs of neglect are becoming unsustainable.

Pipeline vandalism alone accounts for billions in losses annually. The Nigerian National Petroleum Company Limited (NNPC) estimates that crude oil theft and sabotage cost the nation more than $2 billion in recent years. On the offshore front, corrosive saltwater conditions, limited access to skilled manpower, and logistical difficulties mean equipment often deteriorates faster than expected. Deferred maintenance amplifies risks, shortening the useful life of multibillion-dollar assets.

Industry experts warn that the longer companies postpone strategic asset integrity management, the more expensive recovery becomes. Failures trigger production shutdowns, lawsuits, and reputational crises, while also undermining investor confidence. In a region where energy infrastructure underpins government revenues and foreign exchange earnings, the ripple effects extend far beyond company balance sheets.

Read also: Oil firms revive old wells to cut costs

Asset integrity management

To confront this mounting challenge, local operators are increasingly turning to Asset Integrity Management (AIM), a structured, technical, and strategic approach to ensuring that assets perform safely and efficiently throughout their operational life. AIM is not limited to routine inspections. It spans every stage of an asset’s existence: design, construction, commissioning, operation, upgrades, and decommissioning.

Through methods such as risk-based inspections, corrosion monitoring, non-destructive testing, and predictive maintenance, AIM allows companies to detect vulnerabilities before they escalate into failures. Industry data shows that when effectively implemented, AIM can extend the lifespan of critical infrastructure by over 30 percent while reducing lifetime maintenance costs.

For local oil companies, adopting AIM is about more than regulatory compliance—it is about protecting revenue streams and ensuring competitiveness in a volatile global oil market. In the Niger Delta, operators who have invested in modern AIM systems report fewer shutdowns, improved safety outcomes, and stronger resilience to operational disruptions.

The regulatory landscape: A mixed bag

The Nigerian regulatory environment is complex, with multiple agencies overseeing different aspects of the oil sector. The Nigerian Upstream Petroleum Regulatory Commission (NUPRC), created under the Petroleum Industry Act (PIA), now leads upstream oversight, but its work intersects with agencies such as the National Oil Spill Detection and Response Agency (NOSDRA) and the Nigerian Content Development and Monitoring Board (NCDMB).

While the PIA was a landmark reform, enforcement remains uneven. Overlapping regulations, bureaucracy, and occasional over-regulation have created bottlenecks that discourage proactive investment in infrastructure upgrades.

In contrast, regional peers such as Ghana and Gambia have simplified compliance processes, creating clearer pathways for operators to adopt integrity management practices.

Local oil companies argue that Nigeria’s regulatory framework must evolve further to reward long-term asset sustainability, rather than focusing narrowly on production quotas or penalties after incidents occur. Streamlined rules, aligned with international standards like ISO 55000 and API 580, would not only reduce compliance costs but also foster a culture of preventive care.

Learning from local pioneers

Amid these challenges, some indigenous service providers are demonstrating how local expertise can safeguard infrastructure and extend asset lifecycles.

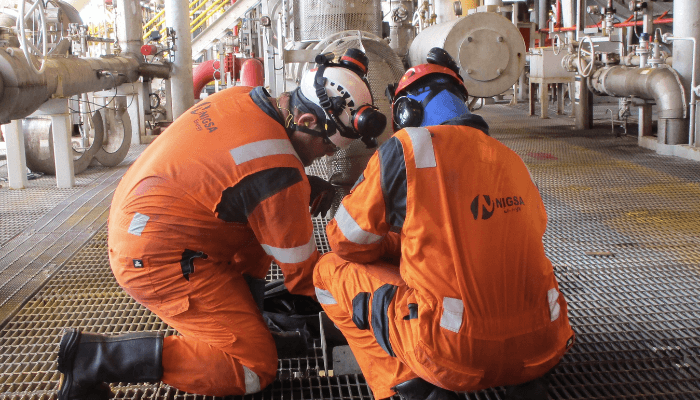

At the forefront are NiGSA Energy and Skysite Offshore West Africa, two firms combining indigenous expertise with international standards to tackle the sector’s toughest challenges, from aging facilities to regulatory compliance.

Read also: Nigeria’s oil production nears 1.83mbpd, targets 2.5mbpd by 2026

NiGSA Energy has distinguished itself as a leader in AIM by providing a broad range of solutions. These include advanced and conventional non-destructive testing (NDT), corrosion monitoring, rope access and rescue services, turnaround maintenance, tank cleaning, and lifting equipment certification. The company also leverages risk-based methodologies grounded in environmental and regulatory knowledge, helping operators enhance reliability and efficiency while managing costs.

Skysite Offshore West Africa, on its part, has carved a niche in delivering conventional NDT solutions while emphasizing predictive and condition-based maintenance. By supporting operators in maintaining assets across diverse terrains, the firm has strengthened compliance with multi-agency regulations, reduced operational risks, and improved safety outcomes. Its strategies have proven effective in minimizing disruptions, extending asset lifecycles, and aligning local operations with international benchmarks.

The impact of these AIM-focused approaches is evident. Both companies have helped operators ensure uninterrupted production, improve inspection efficiency, and enhance overall safety culture across Nigeria’s energy sector. Their contributions are particularly vital at a time when the country faces increasing demands to modernize infrastructure, boost output, and uphold global safety and environmental standards.

NiGSA’s leadership in innovation has also earned it widespread industry recognition. The company has been the recipient of several prestigious awards, including Best Asset Integrity Management Company – Nigeria (2025), Most Innovative Asset Management Solutions Provider – Nigeria (2025), and Most Reliable Energy Sector Engineering Company – West Africa Excellence Award in QHSE Management (2022 and 2023).

These honors underscore its pioneering role in deploying advanced technologies while seamlessly integrating international best practices with local capabilities.

Technology as a Game-Changer

The digital transformation of oil and gas infrastructure management presents a major opportunity for local operators. Digital twins, artificial intelligence (AI), and real-time sensor networks are redefining how assets are monitored and maintained. Instead of relying on reactive responses to failures, operators can now simulate asset performance, predict when equipment is likely to fail, and intervene before disruptions occur.

For instance, deploying sensors along pipelines enables real-time detection of pressure changes that may indicate leaks or tampering, significantly reducing the response time to potential incidents. Offshore platforms equipped with advanced corrosion monitoring systems can be maintained more efficiently, extending their operating lives without compromising safety.

For local companies, embracing these technologies is not without challenges. High upfront costs, limited access to financing, and skills shortages often hinder adoption. Yet the long-term benefits—lower maintenance costs, extended asset lifespans, and improved investor confidence—make digital integration a strategic priority. Partnerships with technology providers, training programs for local engineers, and supportive government policies could accelerate this transition.

The role of finance and policy

No amount of technical expertise will succeed if companies lack the financial resilience to implement robust asset integrity strategies. Economic volatility remains a significant barrier. Oil price fluctuations, foreign exchange restrictions, and tariff reforms often shrink the funds available for infrastructure investment. Smaller local operators, in particular, struggle to balance immediate production costs with long-term integrity spending.

Industry leaders argue that financial institutions, both local and international, need to develop tailored funding models that incentivise preventive maintenance. Similarly, policymakers could introduce tax incentives, cost recovery frameworks, or risk-sharing mechanisms to support AIM adoption. Just as governments provide incentives for renewable energy projects, similar measures for infrastructure preservation could yield significant returns in terms of national revenue protection.

A future built on resilience

Nigeria and other African oil producers stand at a crossroads. As global energy markets evolve and environmental pressures mount, the ability to sustain production safely and responsibly will define competitiveness. Local oil companies that invest in asset integrity today will not only extend the lifespan of their infrastructure but also secure their place in an increasingly demanding global energy landscape.

By combining local expertise, global standards, advanced technologies, and supportive regulatory and financial frameworks, indigenous operators can overcome the challenges of aging infrastructure. The prize is not just fewer spills and longer-lasting pipelines; it is a more resilient energy sector that supports communities, protects the environment, and sustains national economies for decades to come.